| Product Name | EcoCreto |

| Application Projects | In Italy, Mexico, Sweden, and the United States |

| Date | 1996-Present |

| Manufacturer | ECOCRETO |

| Product Design | Jaime Grau, Nestor De Buen |

| Material Use | Concrete Paving |

| Cost per unit | $151.20 USD per cubic meter of additive to concrete |

Previous concrete often eliminates the need for costly stormwater drainage systems and detention ponds. Photo: Nestor de Buen

Estadio Omnilife in Guadalajara, Mexico, is paved with EcoCreto to help with drainage. Photo: Nestor de Buen

Experimenting with different concrete mixtures for paving panels, chemist Jaime Grau stumbled upon a formula that made water-permeable concrete, but discarded it because it leaked. What appeared as a flaw to Grau, architect Nestor de Buen, who spotted the sample tile in the scientist’s lab, recognized as an opportunity. When de Buen learned of the pervious paver he realized it was the solution to a longstanding design problem: how to make pavement that drains like soil.

Concrete is made from aggregate (sand, gravel or other fill) mixed with water and cement. To create a porous concrete, large grains of gravel three-eighths of an inch round are used instead of sand and mixed with cementious or fly ash. Called pervious concrete, the technique has been in use for many years. However, it is difficult to mix. Too much water and the aggregate gathers at the bottom, too little and it doesn’t bond correctly—so it can only be installed by specialists. “Additives like EcoCreto reduce the skill needed by installers and the mixture plant,” explains Michael Bledsoe, president of Pervious Concrete, based in the state of Washington, USA. “Concrete paving need to hold together for decades with cars and trucks passing over it, and it has to drain well. These additives increase the chance that an inexperienced crew can install it successfully.”

Grau and de Buen named their product EcoCreto and later sold the technology. It is one of a number of new chemical compounds introduced in recent years that slow the hydration process. The concrete does not need to be covered to prevent water from evaporating and it allows for a greater tolerance in a range of temperature conditions.

Mixing cement and additives with large grains of gravel rather than sand, a typical concrete ingredient, allows water to pass through EcoCreto pavers at a rate of 4 inches per minute (240 in per hour). Water will still drain through at 4 inches per minute, if up to 40 percent of the voids in the concrete are compromised. Although it can become clogged with dirt and debris over time, pressure washing restores the concrete’s effectiveness.

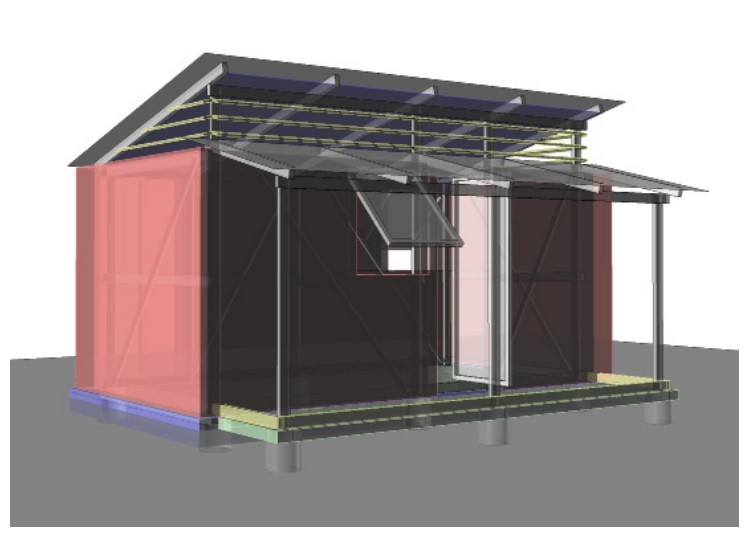

EcoCreto is applied like asphalt, laid over a sub-base of stones and a geo-textile fabric. Wire and rebar are not recommended, as the water coming through the cement will cause them to rust. Even though it’s porous, the cement is relatively strong. A 4-inch section can support 3000 pounds per square inch (psi) within 24 hours, and 5000 psi within 28 days. Freezing temperatures do not compromise its effectiveness, according to Dr. Robert Roseen, of the University of New Hampshire Stormwater Center, which found that a porous concrete parking lot on campus functions equally well in all seasons.

Added benefits of the water-permeable concrete include cooling paved areas and cleaning drained water. Air pockets in EcoCreto retain less heat than asphalt or conventional concrete, which can raise a city’s temperature to be 8 degrees warmer than surrounding open space. And the large grains that allow water to percolate through EcoCreto also filter pollution particulates.

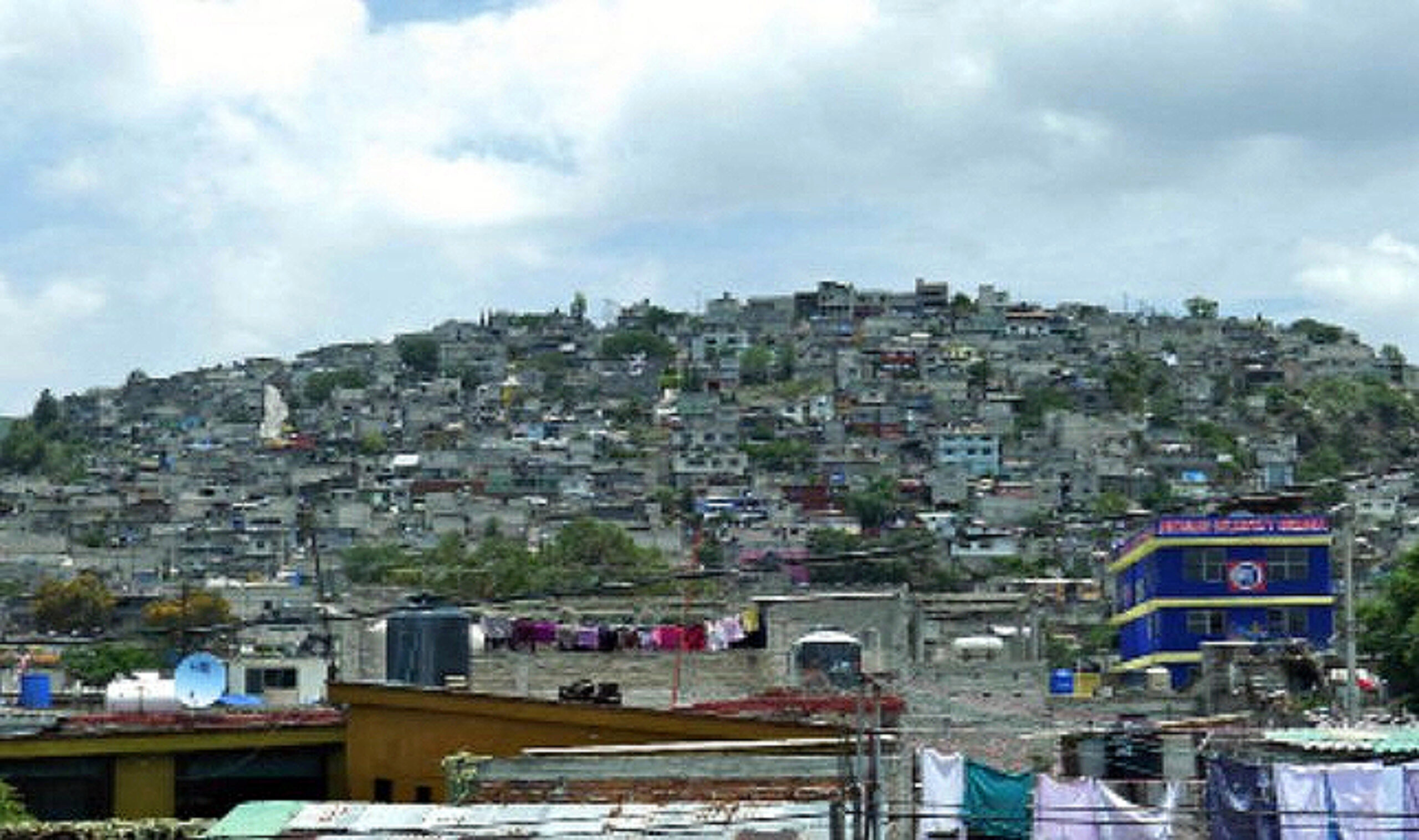

Pervious pavement offers hope for urban areas facing water crises. Mexico City, for instance, receives nearly 30 inches of rain per year, usually in heavy bursts during the summer. The risk of flooding has led the city to create a series of canals and drains that divert the water out of the city and directly to sea. Consequently, the aquifers under Mexico City are not being replenished and the water table is dropping by as much as 1 meter per year in some parts of the city, making it harder to extract water from the 450 wells that supply 70 percent of the city’s water, according to Mexico City water officials. The depletion of the city’s extensive aquifers makes the soil shift and sink, causing numerous foundational problems for the city’s roads, sidewalks and buildings, which can tilt and rise in unpredictable and dangerous ways.

As more people become familiar with best practices around stormwater management, pervious concrete holds promise. Ironically, a product once considered a mistake could now become an important tool in the push for greater sustainability.

READ OR LEAVE A COMMENT