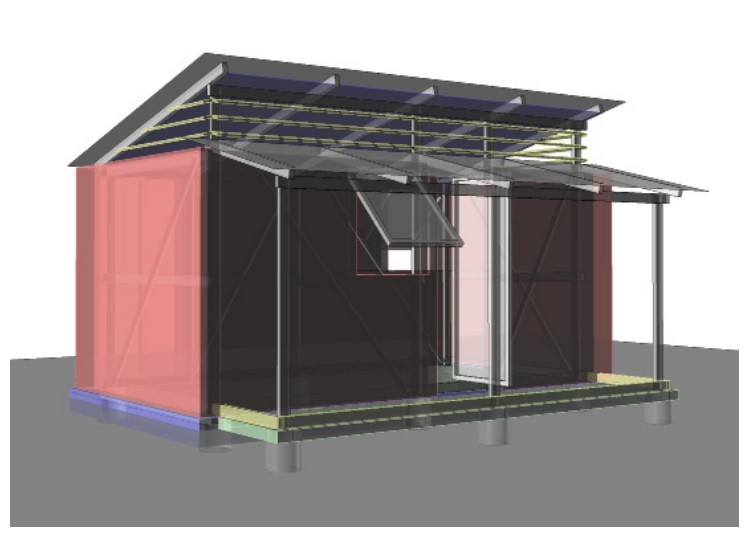

Basic assembly sequence for the “building in a bag”. Images Peter Brewin, William Crawford

| Date | 2003–4 |

| Design Team | Peter Brewin, William Crawford |

| Cost per unit | $2,000 (prototype) |

| Area | 172 sq. ft./16 sq. m |

| Weight | 507 lb./230 kg |

| Website | www.concretecanvas.org.uk |

Invented by Peter Brewin and William Crawford, engineers at the Royal College of Art, Concrete Canvas is a “building in a bag.”

Inflate the bag, and 12 hours later a Quonset-shaped structure is ready for use. Its designers, who both had military backgrounds before pursing their master’s degrees in industrial design, believe the structure could be well suited to housing field operations, emergency medical clinics, or storing food and equipment.

Here’s how it works: First, position the sack of cement-impregnated fabric and fill it with water. (The size of the sack controls the water-to-cement ratio, eliminating the need for measurement.) Then leave the bag for 15 minutes while the cement hydrates. A clothlike fiber matrix and water-absorbent bonding agents draw water, creating a chemical reaction that mixes the cement. Next, unfold the structure, which then inflates like an air mattress via a chemical pack that releases a controlled volume of gas. Once the structure inflates, leave it to harden and then cut doors and ventilation holes out of the concrete “cloth.” Finally, leave the concrete to cure overnight. (To avoid overdrying, the structure should be deployed at dusk.) The result is a thin concrete structure of 172 square feet (16 sq. m). A plastic inner lining bonds with the concrete to create a sterile waterproof interior.

Basic assembly sequence for the “building in a bag”. Images Peter Brewin, William Crawford

Although the idea of delivering instant shelter in a bag is intriguing, at 500 pounds (230 kg) the sheer weight of the sack precludes distribution by foot and requires a lightweight truck. Also, water can be scarce in an emergency. Field operations tend to relocate as political and environmental concerns dictate, and the permanent nature of these structures raises questions such as how to dispose of the building or repurpose it once it is no longer needed for emergency use.

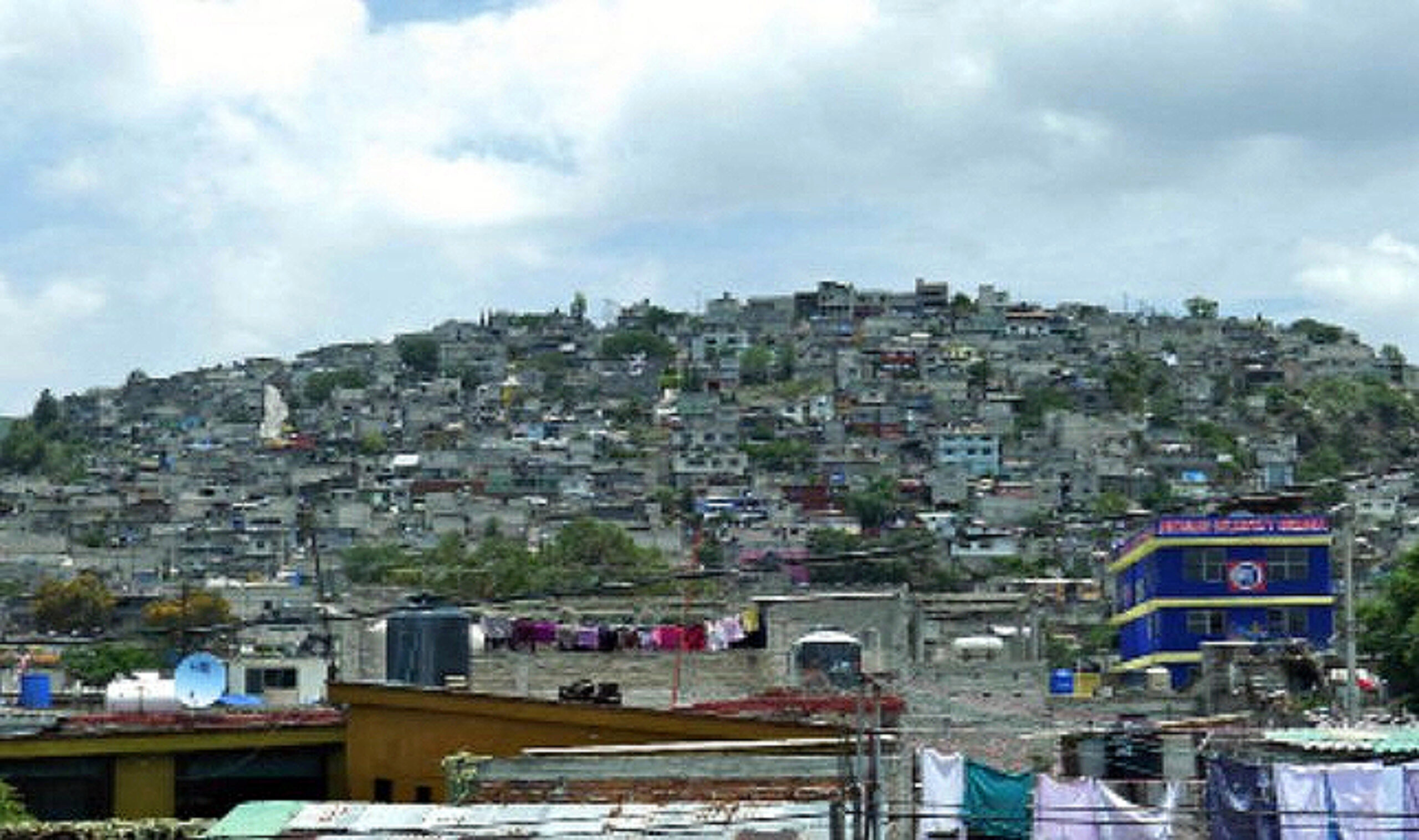

That said, Brewin and Crawford have developed a number of small-scale prototypes. Last year Concrete Canvas won the Sustainable Design Award from the British Standards Institute, which allowed the team to conduct field research in Uganda. They have filed a patent on the technology and plan to continue to develop the idea.

“If this was available now, we would buy 10 today.”

Monica Castellarnau, Médecins Sans Frontières, Uganda

READ OR LEAVE A COMMENT