Both photographs I-Beam Design

| Location | Bronx, New York, USA; Ball State University, Muncie, Indiana, USA; Sri Lanka |

| Date | 1999–present |

| Design Firm | I-Beam Design |

| Design Farm | Azin Valy, Suzan Wines |

| Additional Support | Chris Teeter, Dr. Wes Janz, Ball State University students and faculty |

| Construction | Volunteer Labor |

| Major Funding | LEF Foundation, New York State Council on the Arts |

| Cost per unit | Approx. $200 (donated pallets); $1,700 (purchased pallets) |

| Area | 1,200 sq. ft./110 sq. m |

Suzan Wines and Azin Valy’s firm, I-Beam Design, was only a year old when the team first experimented with the Pallet House.

In 1999 they entered the design in Architecture for Humanity’s Transitional Housing competition for returning Kosovar refugees. Since then I-Beam has made significant progress toward realizing its vision of a viable disaster-relief architecture using standard shipping pallets—which are often in great supply in disaster situations because of the influx of aid—as the base component of a modular building system.

After winning an honorable mention in the competition, the team developed the project further, and with funding from the New York State Council on the Arts and the LEF Foundation it has been testing the Pallet House system at increasingly ambitious scales. The team’s first dwelling-size prototype was assembled on a vacant lot in New York’s South Bronx. Although the Bronx project was short-lived—bulldozed by the city soon after it was finished—in the brief period it was standing the structure became a temporary home to one of the city’s homeless.

In fall 2004, at the invitation of architect Dr. Wes Janz, I-Beam led a four-day building workshop that challenged students at Ball State University, in Muncie, Indiana, to develop housing types using the pallet system. The 35 students and four faculty members collected 500 pallets and built six pallet structures in three days, using only basic carpenter’s tools. The workshop resulted in a variety of dwelling structures accommodating a range of living arrangements and including the construction of integral furniture. The students also experimented with creating different types of public spaces between the structures. The school kept the prototypes in place for a number of weeks. According to Janz, during that time they became well-used classrooms and lounges, turning an ordinary lawn into a lively communal space—and encouraging participants that a similar transformation could be achieved elsewhere.

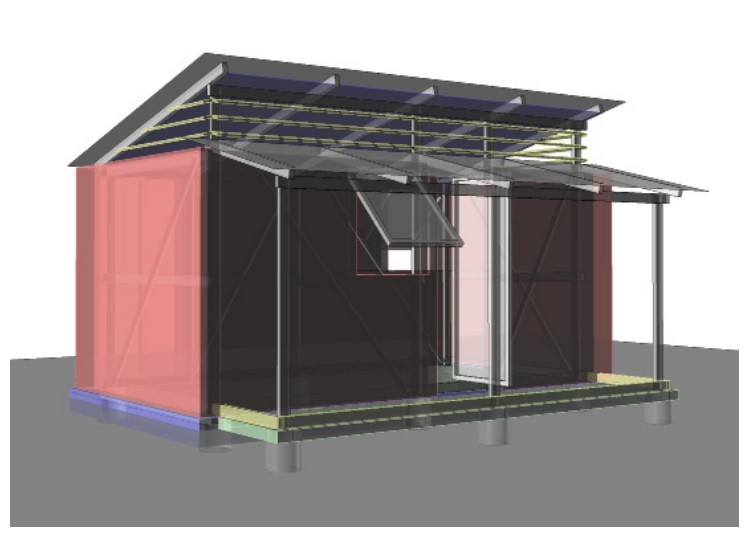

In response to the tsunami that struck Southeast Asia in 2004, the architects adapted the Pallet House system again—this time designing a basic 1,200-square-foot (111-sq.-m) dwelling, using 300 pallets, for use in Sri Lanka. The Sri Lankan scheme also provided an opportunity to think about how the Pallet House concept could respond to various climates. For example, to manage Sri Lanka’s heat and humidity, I-Beam adopted the local building practice of leaving space between the top of the walls and the roof for air circulation. In other climates the pallets could also be filled in with wattle-and-daub or other locally appropriate insulation.

I-Beam has always thought of the Pallet House as transitional housing, an immediately constructible and sturdy alternative to a tent in a disaster situation. Drawbacks include the labor-intensive nature of the design and the fact that pallets come in various sizes and materials, which can hamper construction. That said, shipping pallets are widely available. Reusing them offers the potential to lessen deforestation. And perhaps more significant, pallets are prefabricated, which makes them a natural building material.

The design adapted for use in Sri Lanka after the Indian Ocean tsunami. Chris Teeter

The pallets can be plastered in wattle and daub or filled with straw, rubble, or other material for insulation. I-Beam Design

READ OR LEAVE A COMMENT