| Location | Rwanda |

| Date | 2008-10 |

| Implementing Agency | SHE (Sustainable Health Enterprises) |

| Campaign | SHE28 |

| Design Team | Kayibanda Ingabire Julian, Elizabeth Scharpf |

| Product Research and Development | Teams from the Massachusetts Institute of Technology and North Carolina State University |

| Product Design | SHE |

| Franchise Start Up Cost | $28 000 |

| Cost of Machine | $1500 |

| Recognition | 2010 Curry Stone Design Prize |

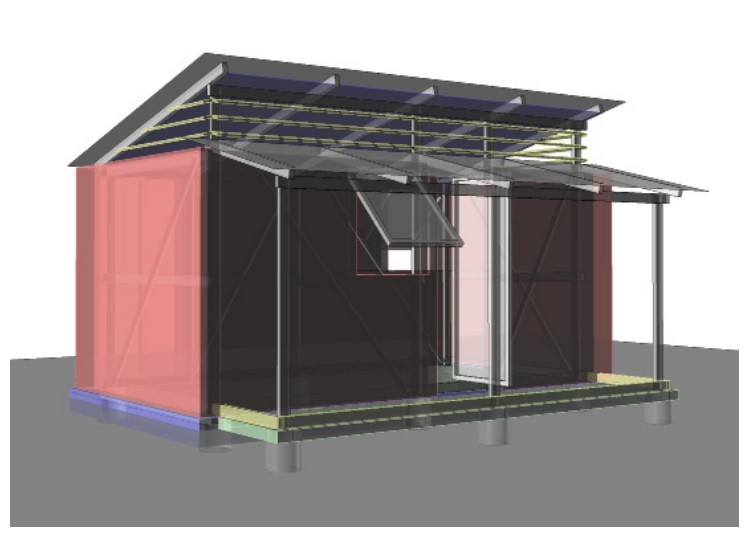

SHE Launch Pad made of local Rwandan banana fibers. Photo: Carrie Wisler/ Sustainable Health Enterprises

On a visit to Mozambique in 2005, Elizabeth Scharpf heard a statistic that nearly half of girls and women in Rwanda miss school or work when they are menstruating because menstrual napkins are too expensive. “I thought that was wrong,” Scharpf says. “I decided to do something about it.”

Scharpf founded Sustainable Health Enterprises (SHE) in January 2009 while attending the Harvard Graduate School of Business. Today the organization is working in Rwanda on three different initiatives—awareness, education and products—with the goal of providing women affordable access to menstruation solutions.

In Rwanda the least expensive brand of sanitary pads sells for $1.10 a pack, more than a typical day’s worth of wages for most, and without pads, women commonly turn to substitute rags, bark or mud for protection. There is a significant cultural taboo against discussing menstruation, especially in the company of men.

SHE is in the process of producing a menstruation pad and planning to sell the Launch Pads in Rwanda. The banana fiber pads will be made by hand in the communities in which they are sold. The organization hopes to sell the pads for less than $1 for a pack of 10, which is 30-35 percent cheaper than the generic brand that is currently available to them.

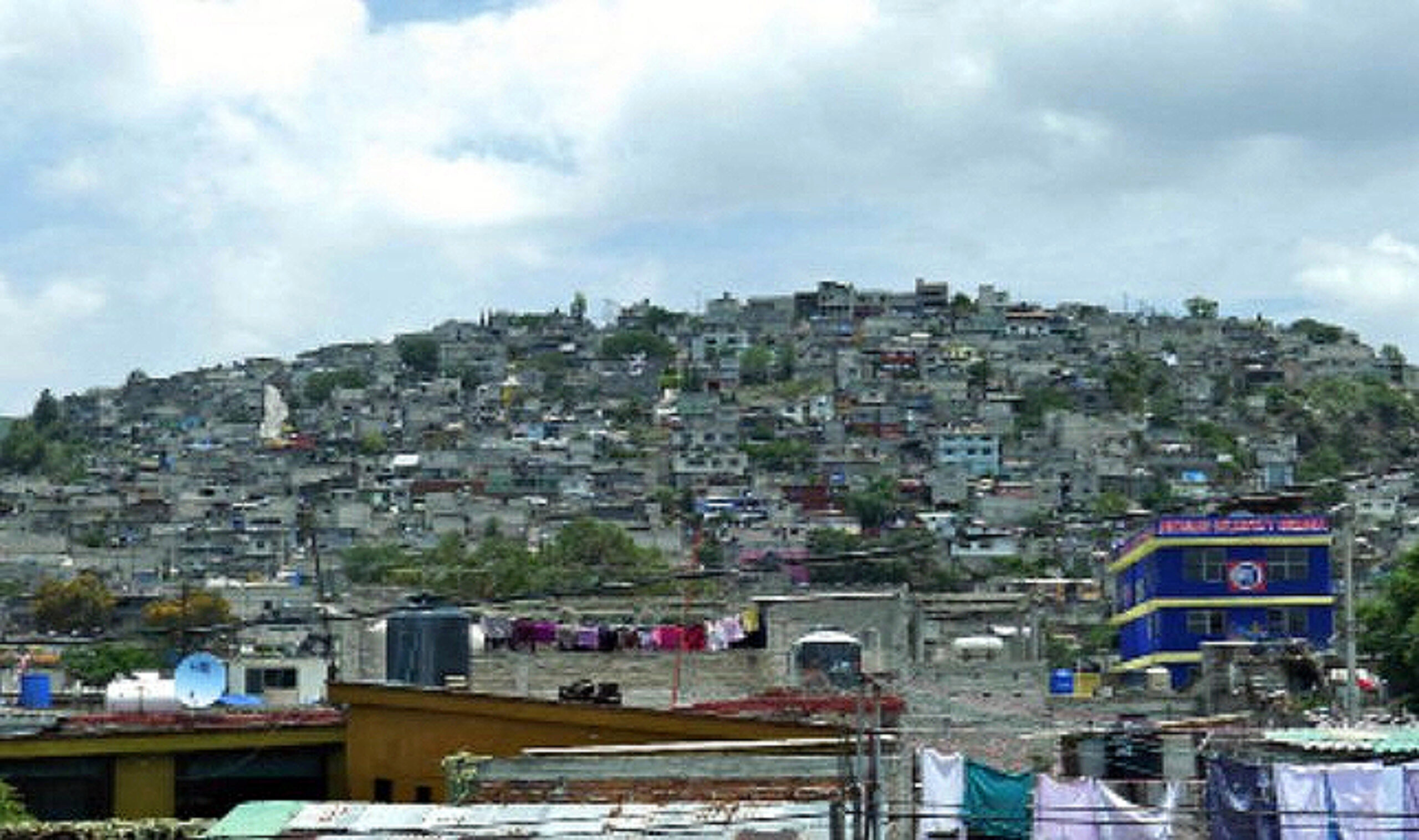

Women from the Rwandan community of Ngoma extract banana fiber for the production of a sustainable menstrual pad. Photo: Hannah Poole/Sustainable Health Enterprises

Finding a material that was both highly absorbent and abundant was a challenge. With help from researchers from North Carolina State University, SHE settled on banana fibers, a local agro waste product from the trunks of banana trees. “The challenge for SHE was to determine whether it was possible to come up with a low-cost, low-energy processing method to convert banana stem fibers into an absorbent pulp,” explains Dr. Marian G. McCord, director of global health initiatives and professor of textile engineering at the university. A team from the Massachusetts Institute of Technology joined in and developed a chemical-free method for processing banana fibers.

SHE put all the pieces together to produce a prototype with adhesive, and scaled down the manufacturing process so that the pads could be made in an electricity- and cost-constrained environment. So far 50 women have been trained in different parts of Rwanda. They eventually set up a franchise operation. SHE is also training community health workers to give talks at schools and community events, not only on menstruation, but on various health topics such as malaria, maternal health, and hygiene.

Community health workers deliver menstrual health and hygiene education to school girls in eastern Rwanda. Photo: Elizabeth Scharpf/Sustainable Sustainable Health Enterprises

READ OR LEAVE A COMMENT