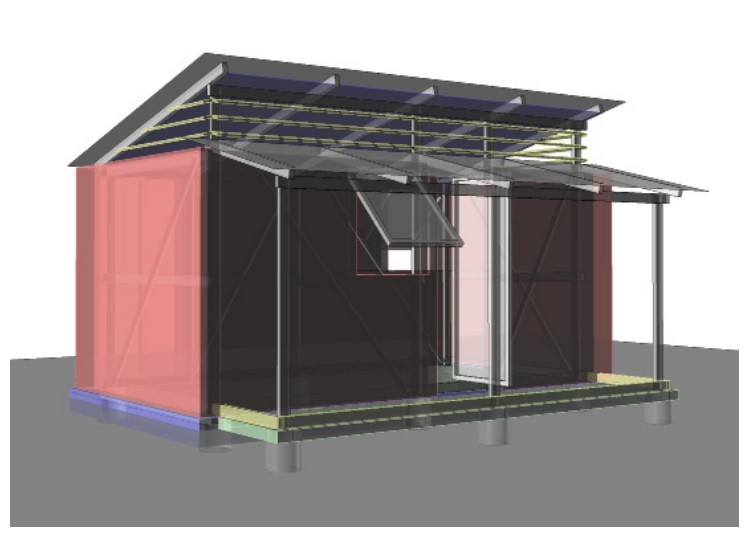

The 10×10 Houses in Cape Town, South Africa. Weiland Gulch/Design Indaba

| Implementing Agency | Design Indaba |

| Featured Project | Sandbag House |

| Location | Mitchells Plains, Cape Town, South Africa |

| Date | 2007-9 |

| End User | 10 Freedom Park Settlement families |

| Design Firm | MMA Architects |

| Design Team | Luyanda Mpahlwa, Uli Mpahlwa, Sushma Patel, Kirsty Ronné |

| Contractor | Chinedum Emeruem, Westley Van Wyk |

| Material Supplier | Mike Trenmere: EcoBuild Technologies, supplier of EcoBeams and Sandbag technology, Schalk Van Der Walt–Tech Homes |

| Quantity Surveyors | Brian Mahchi-BTKM Quantity Surveyors |

| Funders | Design Indaba Trust; PG Bison/Pennypinchers |

| Cost per unit | 65 000 South African rand/$8200 USD |

| Area | 500 sq m/5381 sq ft |

| Occupancy | 6 people |

South Africa’s post-apartheid Reconstruction and Development Programme provides brick and concrete mortar houses to people who need them through a program that provides subsidies to private housing developers. The current government subsidy per house is 50 000 South African rand, or $6900. Design Indaba challenged architects to design an alternative to the standard government-funded design with which many people were unhappy. The Cape Town-based [design advocacy] organization organized the 10×10 Housing Project competition. In 2007, they invited 10 teams, each consisting of one international and one South African architect, to design a house for a family in Mitchells Plains township, an informal community 25 miles (40 km) from the heart of Cape Town.

The winning design by MMA Architects employs sandbags as a sustainable building material. Sandbags can be used as affordable and effective insulation and offer added protection from weather. “We’ve got to find different ways of uplifting the people and one of them is obviously going to have to be sustainable building because you’ve got millions and millions of people,” says Luyanda Mpahlwa, a principal architect at MMA Architects. “You can’t use the conventional ways, which use high energy and increase the carbon footprint.”

The winning design uses EcoBeams, a product of a South Africa-based company, to frame the house. The vertical beams are made of timber connected with a galvanized metal element. Nylon bags filled with sand are stacked within the frame and covered with mesh wire and plaster to form smooth walls. These houses do not need foundations and the sandbags act as the anchoring element to further reduce construction costs.

The Pillay family, one of the clients for the Design Indaba house competition. Photo: Yasser Booley/Design Indaba

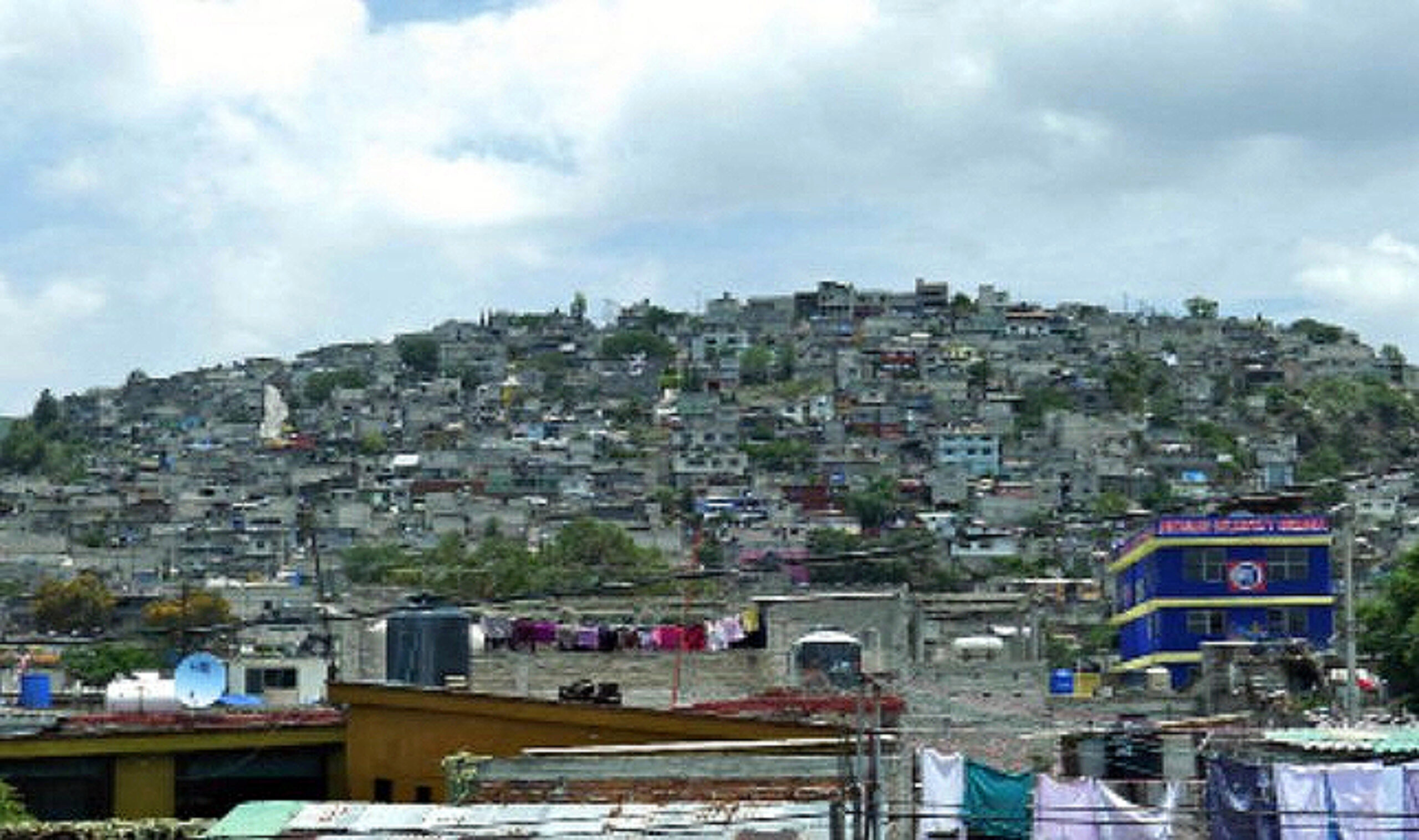

Freedom Park, South Africa. Photo: Yasser Booley/Design Indaba

Community members packing sandbags against wooden cladding. Photo: Nadya Glawe/Design Indaba

Applying plaster scratch coat. Photo: Nadya Glawe/Design Indaba

Framing the second floor of the house. Photo: Nadya Glawe/Design Indaba

Construction of the second floor. Photo: Nadya Glawe/Design Indaba

The second-floor terrace acts as a carport and can be converted into an additional room. Photo: Wieland Gleich / Design Indaba

Sandbags had been used in South Africa but the designers pushed boundaries by building a two-story sandbag home. Expanding vertically helps to maximize living space on small plots of land. “We had to be very creative about how we would use sandbag building technology because we were not aware if it had been used before,” Mpahlwa says. “We had to get the services of an engineer and he had to be innovative about how to support the top structure.” Concrete beams were placed on top of the first-floor walls to ensure structural stability, and a concrete beam acted as foundational element for the second floor.

Ten homes were built from the design and 10 families are now living in them. Each house has a second-story platform that the occupants can use as a patio or make into an additional room. The homes were all placed close to the road to create the largest backyards possible. “We used architecture as a way of empowering a community that has never had a house before,” Mpahlwa says.

READ OR LEAVE A COMMENT