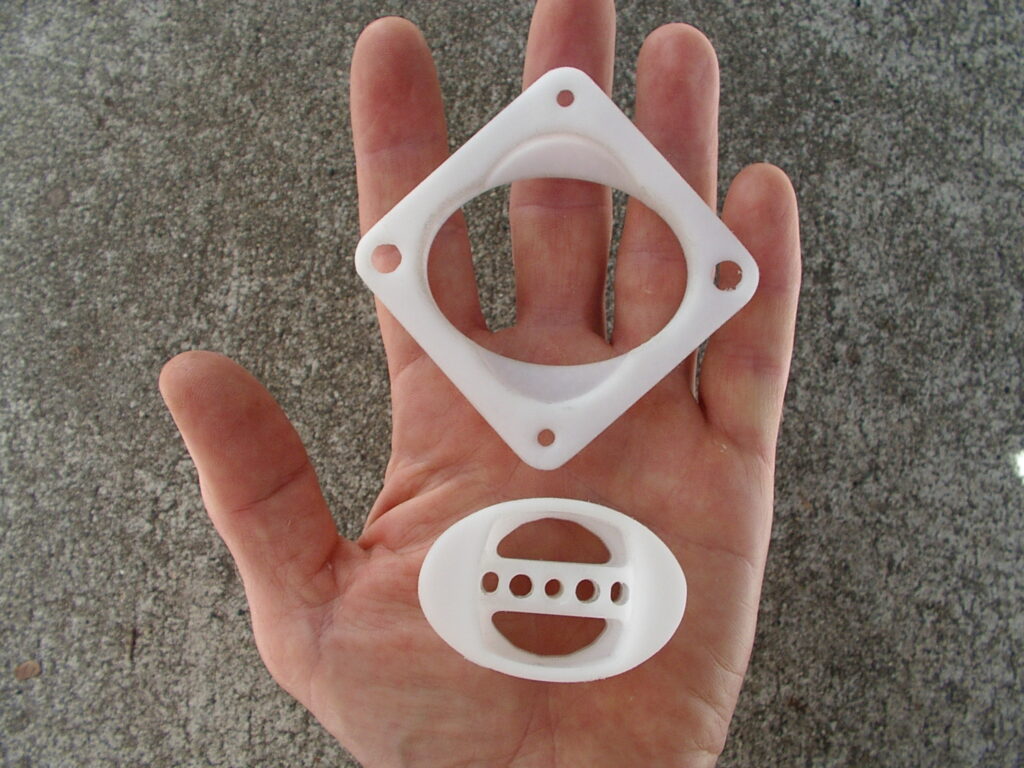

A GripClip, secured to a cross-piece of frame, shown from inside a shelter. The frame pieces are secured with plastic wrap.

| Location | Various |

| Date | 1975–present |

| Designer | Robert Gillis |

| Manufacturer | Shelter Systems |

| Cost | $8–10 (set of 4) |

It would be safe to say that few people know the ins and outs of tents better than Robert Gillis.

Not only did he design the first geodesic backpacking tent, based on Buckminster Fuller’s ideas, for The North Face in the 1970s, but he also lived in a collection of tents (with his wife and three children) for more than 20 years—all of which he designed himself, including the tent that housed the family washing machine.

Although many of Gillis’s tent innovations have stemmed from efforts to improve his own living conditions, from the beginning he saw the potential for translating his ideas to emergency shelter—in particular using the plastic sheeting that has become a standard component of relief projects. However, working with plastic sheeting meant finding a way to “hold on to it.” Gillis explains: “It was difficult to join the material without puncturing it. But puncturing it is a bad idea because it weakens it. The material deteriorates less if you don’t injure it.” The designer went through more than 10 different iterations before arriving at the GripClip, a small plastic fastener that clips onto any type of sheeting and ties it

to a frame.

GripClip’s two plastic parts are designed to be twisted together with a piece of sheeting between them. The clip itself can be fastened to a frame structure with plastic ties, rope, or pipe clamps.

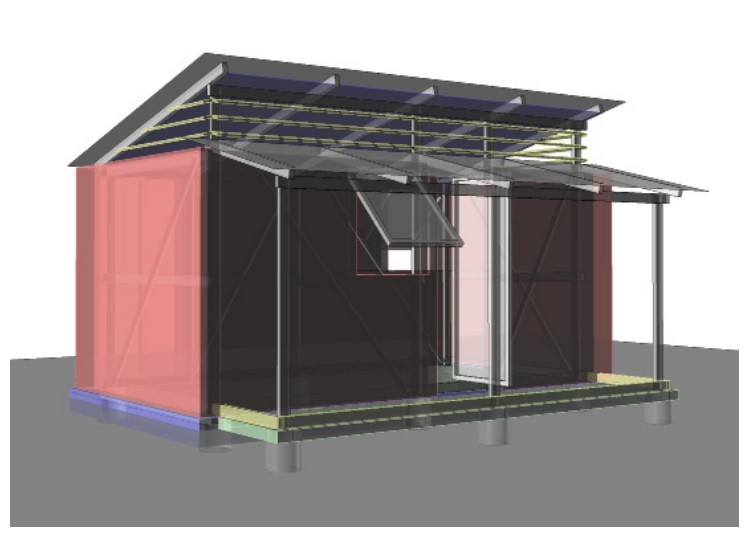

Reducing the shelter to its most fundamental element, the connection between the sheeting and the support, enabled Gillis to design a number of tents, from a basic shelter frame kit to more elaborate dome structures.

The clips also offered another advantage: They allowed for a range of shapes. Whereas most relief agencies distribute tunnel-shaped tents because the structure can be covered with one large sheet of material, these tents are less stable in the wind than dome-shaped tents. Using GripClips, Gillis found he was able to layer sheeting in shingles to create a more stable structure that would also shed rain. “And I didn’t have to sew it or heat-weld it or anything,” he recalls. “Here was the perfect thing: It was totally wonderful.”

More recently Gillis has focused on creating clips and fasteners to attach plastic sheeting to roofs, frameworks, piping, or plywood, allowing families to turn damaged structures into transitional homes while they rebuild.

Robert Gillis inside a tent built with GripClips. All photographs © www.dometents.com

READ OR LEAVE A COMMENT