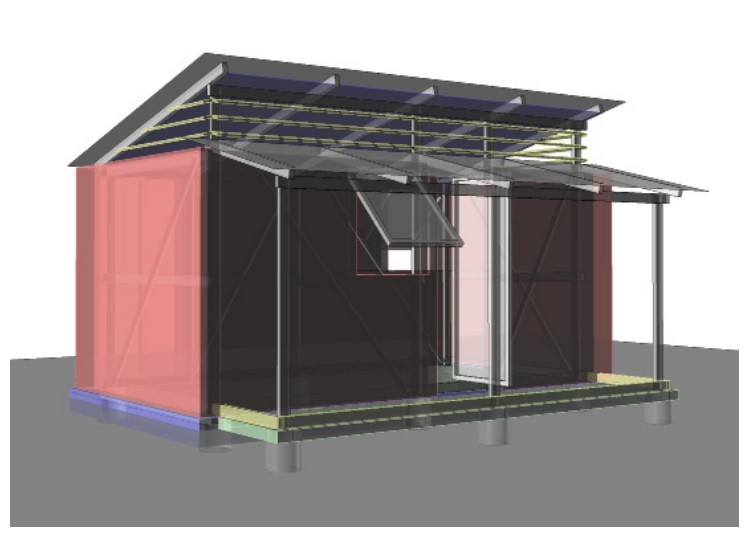

Inflated hemp structure prior to application of thin concrete shell. The wooden frames, or “Life Elements,” support the structure, form doors, and contain core services.

| Location | Japan |

| Date | 1999-present |

| Design Firm | TechnoCraft |

| Design Team | Ichiro Katase, Takashi Kawano, Takeshi Chiba, Ken Takeyama |

| Additional Consultants | Japanese government, Peace Winds Japan, UNHCR |

| Major Funding | Self-funded |

| Cost per unit | $1,800 (prototype) |

For years the architecture group TechnoCraft has explored the role designers can play in responding to crises by using innovative materials and low-tech construction.

When the team entered its Low-Tech Balloon System into Architecture for Humanity’s 1999 Transitional Housing competition, the quirky yet feasible design generated delight and surprise. Jurors dubbed it the inflatable hemp house.

Hemp is one of those materials that tend not to be taken seriously. (Indeed, during the jury process one of the panel members joked, “If there was a fi re, would anyone leave?”) Still, in many parts of the world hemp is an abundant natural resource that if used correctly is an inexpensive, strong, long-lasting option.

The scheme is by far one of the most unusual transitional structures Architecture for Humanity has come across. But while it might be tempting to dismiss the system as yet another fanciful architectural detour, the team was able to erect its first prototype in a single day. With input and advice from the UNHCR in Japan and the NGO Peace Winds Japan, the architects went on to make four more prototypes with modifications, including a mobile health clinic version for the 2002 Architecture for Humanity OUTREACH design competition.

The idea is to take used hemp sacks, in this case animal feedbags, and sew them together to form a dome-shaped structure. The construction is separated into fabricated elements that can be assembled off-site or by a local cottage industry “build-up process” at the site. Separating the production process allows for faster production and eliminates the need for electricity.

At the site the sewn hemp “skins” are connected by plastic ties and attached to “Life Elements” (doors, windows, and facilities for cooking, sanitation, and storage) with a maximum of eight per structure. Workers stuff the hemp structure with inflated airbags or balloons, tighten the plastic ties to increase the air pressure, and dampen the entire structure. They then spray or apply mortar over the dome to create a thin concrete shell, much like a papier-mâché model. Inner pressure from the airbags supports the structure during the mortar application, making additional construction devices such as an air-compressor or wooden supports unnecessary.

Once the mortar has dried, teams cut out excess hemp from the openings of the doors, windows, and other elements and deflate the airbags, which can be reused. Then workers mortar and plaster the interior walls, creating a waterproof, thermal-insulated shell. Individual units can be easily combined to create larger living spaces.

Time-lapse images of the shelter being inflated. All photographs TechnoCraft

READ OR LEAVE A COMMENT