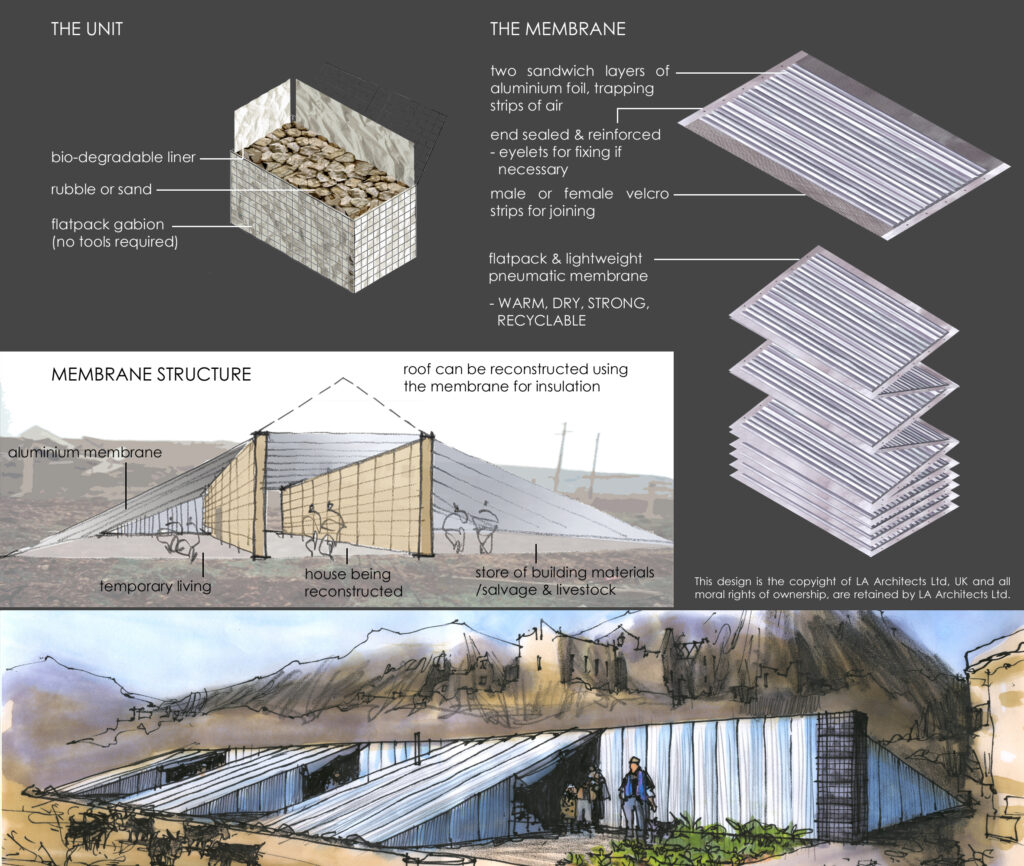

Proposed transitional shelter. Flatpack gabion mesh frames are filled with rubble to form the walls. Panels made from two sandwiched layers of aluminum foil are joined by Velcro to form the roof. Lawless and Whitby conceived of the design in response to the 1999 confl ict in Kosovo but have since adapted it for use in other areas. Chris Teeter

| Location | Essex, England (prototype) |

| Date | 1999–present |

| Design Firm | LA Architects |

| Designer | Mike Lawless |

| Engineer | Mark Whitby, Whitby Bird Engineeers |

| Funding | Self-funded |

Many crises leave behind large quantities of rubble, usually from homes and buildings destroyed by natural disaster or war.

A number of designers have tried to tackle the challenge of how to repurpose rubble to create structurally sound housing and in the process clear the land while providing a sustainable, low-cost shelteralternative. More often than not the answer is gabion wall construction.

Gabions are walls built by filling large baskets with broken stone. Typically the baskets are made from galvanized steel mesh, woven aluminum strips, or plastic mesh, but they have also been made from wickerwork or bamboo slats. The strength of these walls comes from the combination of the weight of the stones and the interlocking and frictional support of the mesh.

For Architecture for Humanity’s 1999 Transitional Housing Competition for Refugees Returning from Kosovo, a number of designers employed gabions. One of the most successful proposals was by Mike Lawless of LA Architects and Mark Whitby of Whitby Bird Engineers.

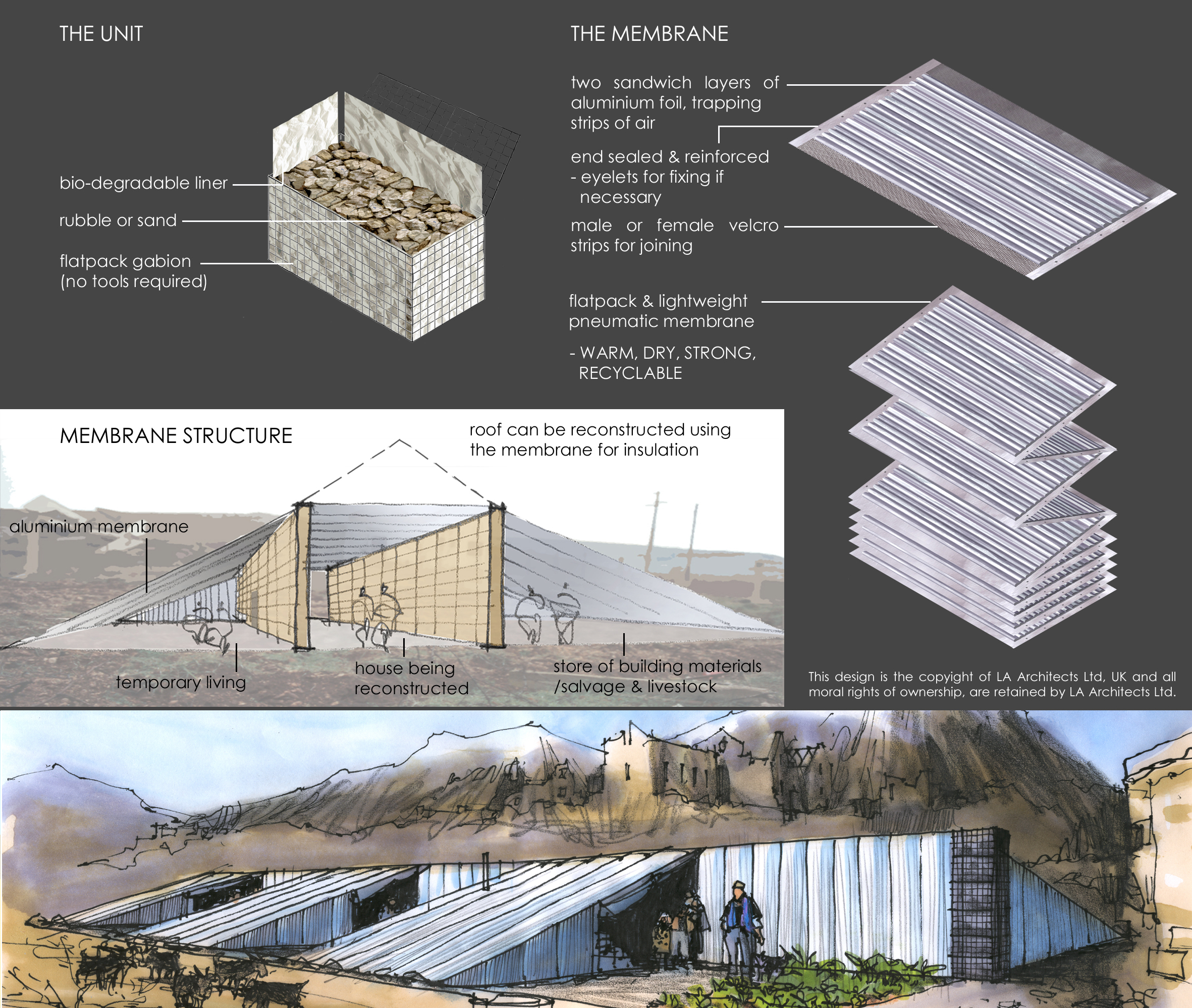

Their system arrives to the site packed flat. A team assembles the wire gabions with rods for structural integrity, then forms walls with the gabions and fills them with rubble. A lightweight aluminum membrane forms a roof, which is then clad with quilted, nylon-reinforced aluminum foil. “It’s not just a saggy, aluminum fabric but quite a rigid, well-waterproofed and -insulated building material,” says Lawless. Velcro connects the roof’s edges to create a fully weathered seal. The entire system snaps together and requires no tools to assemble.

In 2000 the designers constructed a full-scale prototype in Essex, England, as part of an exhibition at the Spacex Gallery. The unit took a team of 10 people less than six hours to build.

READ OR LEAVE A COMMENT