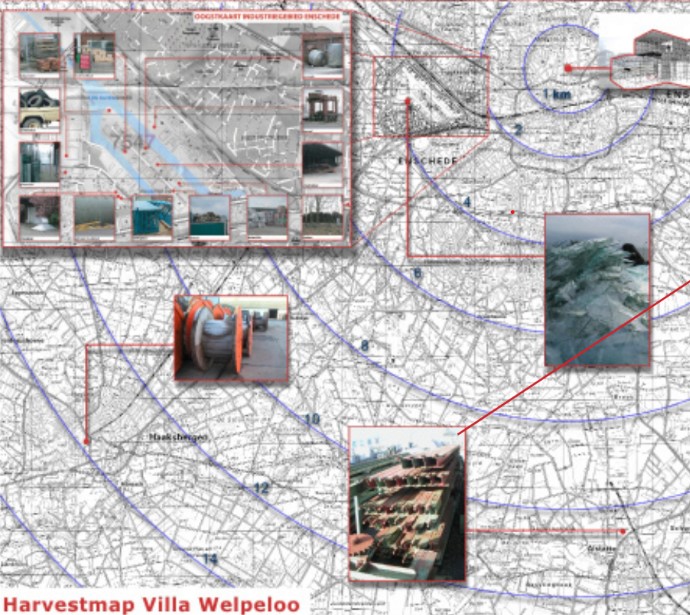

The Harvest Map displays recycling opportunities. Image: 2012Architecten

| Featured Project | Villa Welpeloo |

| Location | Enschede, Netherlands |

| Date | 2006-9 |

| Client | Knol and Blans family |

| Design Firm | 2012Architecten |

| Design Team | Jeroen Bergsma, John Bosma, Frank Feder, Jan Jongert, Petra Jutten, Carolien Karamann, Iris de Kievith, Jos de Krieger, Wojtek Witek |

| Contractor | Den Boer Bouwen en Installeren |

| Cost | €900 000/$1.3 million USD (owner funded) |

| Area | 400 sq m/4305 sq ft |

| Program Cost | €3000-€8000/$4267.50-$11 380 USD |

| Web Resource | www.superuse.org |

The 2012Architecten Harvest Map uses Geographic Information System technology to locate and log found materials. It analyzes and catalogues otherwise landfill-bound products in a database that makes them available for projects varying from houses to children’s playgrounds. 2012 Arkitekten has taken the gathering instinct into the 21st century with the concept of “superuse.” Superuse is material harvesting on steroids. “It is about how material waste flows can be used in architecture,” says Jan Jongert, 2012 Arkitekten principal architect. The firm created Superuse.org, a Website devoted to displaying inventive uses of post-consumer and discarded materials. The Harvest Map project seeks out materials in close proximity to a building site to minimize transportation costs, and Superuse aims to minimize the alteration of those materials to further lower their energy impact. Though much of the materials are used waste such as car tires, they are exploring pre-consumer waste such as sample materials and new products that cannot be sold. The project also makes use of industrial infrastructure that can be disassembled into new configurations.

Jongert sees no limits to where Superuse can go. “It is a way of thinking that can be applied to any industry,” he says. He uses teaching and artwork to test it. “We experiment with materials that are more like art or installations, and the knowledge we get we develop more and use in our professional work,” Jongert says. In one instance, he built a coffee kiosk from old washing machine doors.

Search techniques range from driving around aimlessly, to studying an area’s historical industries, to using satellite imagery to stake out the products. “We use Google Earth because some things are so big and well photographed that you can actually recognize the materials,” Jongert says. They’ve procured items like windmill wings this way.

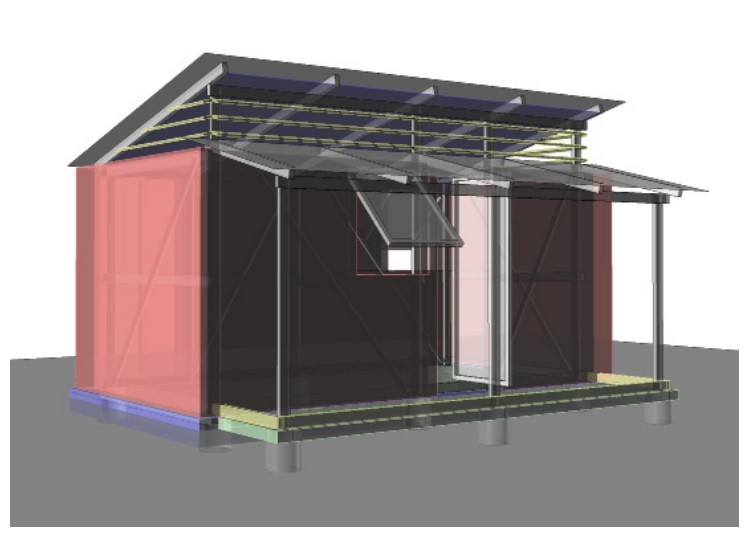

Superuse requires a lot of flexibility from the architect. “We keep on designing while construction is going on, adapting plans according to the materials that are actually being found and used,” Jongert says. Homeowners also need to be patient and flexible. Since the materials are not brand new there is no warranty or guarantee.

In The Netherlands, an eco-home called Villa Welpeloo was designed this way. Owners Tjibbe Knol and Ingrid Blans were invested in seeking out recycled materials. “The recycled materials in their house make up 60 percent of the whole,” Jongert says. Wooden siding is made from old cable reels from a nearby factory and all of the structural steel was harvested from an old textile factory machine. Because they did not know the steel’s specific properties, the engineer suggested they assume it to be the worst quality possible. Although it probably was better than they assumed, since it is secondhand and cheap, using more of it to make up for potential defects was easy.

“I never feel like I am living in a recycled house.”

Ingrid Blans, homeowner

The photos on the top line show the breakdown of a textile machine into reusable structural steel components. Photos: 2012Architecten

left image: The steel components are bolted together to facilitate reuse should the house be deconstructed. Photo: 2012Architecten

middle image: Villa Welpeloo during construction. Photo: 2012Architecten

right image: Completed Villa Welpeloo. Photo: Allard van der Hoek

READ OR LEAVE A COMMENT